cement ball mill election screening equipment

Ball Mill For Cement Grinding – Cement Ball Mill Ball

Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants. It is mainly used to grind limestone, clay, and other cement raw materials, as well as

Read More

Process Training Ball Mill - INFINITY FOR CEMENT

Ball mills for cement grinding usually operate with a filling degree between 25 and 35 %. The filling degree is defined as the volume of the grinding media (balls)

Read More

Ball Mill In Cement Plant - Cement Ball Mill AGICO

Ball mill is the cement crushing equipment in the cement plant. Compared with open- circuit ball mill, the closed-circuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit.

Read More

Process Training Ball Mill - INFINITY FOR CEMENT

BALL MILL OPERATION. Ball mills for finish grinding cement usually consist of two compartments. An intermediate diaphragm separates both compartments from each other. The 1. compartment is filled with coarser balls and lifting

Read More

sbm/sbm cement ball mill election screening equipment.md at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

ball mill and screening - Capabuild

Crsine HTML Template For Car Services. Ball Mills - 911 Metallurgist. Dec 23, 2017 In these cases, the feed to the ball mill may be from 10 to 100 mesh or even finer Where the finished

Read More

cement ball mill election screening equipment

Cement Ball Mill. The cement ball mill in cement plant is usually divided into 2-4 silos, the most representative of which are the "new type of high fineness cement ball mill" and "open flow

Read More

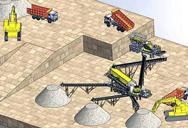

Ball Mill Flotation Machine Mineral Processing Equipment

Mobile Crushing Screening Plant; Mineral line. Gold Ore Dressing ... ball grinding mill, is the key equipment to grind crushed materials into fine powder 20-75 micrometer. It is available in both

Read More

BALL MILL INSPECTION PROCEDURES - INFINITY FOR CEMENT EQUIPMENT

BALL MILL INSPECTION PROCEDURES CLICK HERE NOW TO DOWNLOAD MOST IMPORTANT BOOKS IN CEMENT INDUSTRY + PRACTICAL EXCEL SHEETS TO HELP

Read More

Ball mill for cement grinding

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy

Read More

Ball Mill Manufacturer, Rotary Dryer, Rotary Kiln

Ball Mill Supplier, Rotary Dryer, Rotary Kiln Manufacturers/ Suppliers - Henan Xingyang Mining Machinery Manufactory

Read More

Henan Dingxin Equipment Technology Co., Ltd._Rotary Kiln_Ball Mill

2024.12.31 Ball mill. Externally heated rotary kiln. Multi-channel burner. Mining crushing and screening equipment. Lifting equipment. Conveying and feeding equipment. Case.

Read More

Linear Vibrating Screen - Vibrating Screen Machine In

Cement Ball Mill; Cement Roller Press; ... This screening equipment will not appear material mixing phenomenon. High working efficiency. The screening efficiency of the linear vibrating screen can reach more than 96%. Double

Read More

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure. When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various

Read More

Cement Ball Mill - Cement Grinding Machine - Cement Mill

What Is A Cement Ball Mill. The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various

Read More

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement

Read More

EVERY COMPONENT OF BALL MILL DETAILED EXPLAINED

Fine Grinding and Mill Cooling. PROBLEM. Insufficient mill cooling lead to material agglomeration on balls and liners. The grinding is not any more done by balls against material but by material

Read More

- الكسارات الفك تأ

- سنگ mobie از سازنده سنگ شکن های موبایل استفاده می شود

- البدلات مطحنة من الصين

- طلا کبالت مس جدا

- سيراليون منجم للذهب

- قیمت دستگاه آسیاب توپ سیمانی

- دستگاه سنگ شکن سنگ زنی کوچک

- مطاحن كراتشي كراتشي

- ساعة سحق الخرسانة

- جایگزینی شن و ماسه پودر سنگ مرمر

- تولید سیلیس کوارتز شن و ماسه

- محطة كسارة ثابت

- عملية ترقية خام الحديد في باكستان

- تغار سرند گریزلی ویبراتوری

- سحق إدارة المصنع